Email US:info@kartain.com

|

|||||||||||||||||||||||

Product Description Contact Us

Rogers PCB, High Frequency PCB, RF PCB (Enquiry: info@kartain.com)

With the development of electronic technology,there are electronic products calling for more and more materials,such as Rogers material,which is used for high frequency circuit,making sure that improve electrical performance as used in defense,aerospace and mobile network applications

Rogers is a global leader in engineered materials to power,protect and connect our world.We are passionate about helping the world’s leading innovators solve their toughest material challenges.Rogers is headquartered in Chandler,Arizona,USA, and manufacture products in the U.S.,China,Japan,Korea,Germany,Hungary and Belgium.Their innovative solutions empower the customers’ technological breakthroughs.

What is Rogers PCB

Rogers PCB is one type of printed circuit boards manufactured by Rogers raw material that produce by Rogers Corporation:Rogers is a company who manufactures high frequency laminate materials that are used to produce RF circuit boards or microwave PCB.

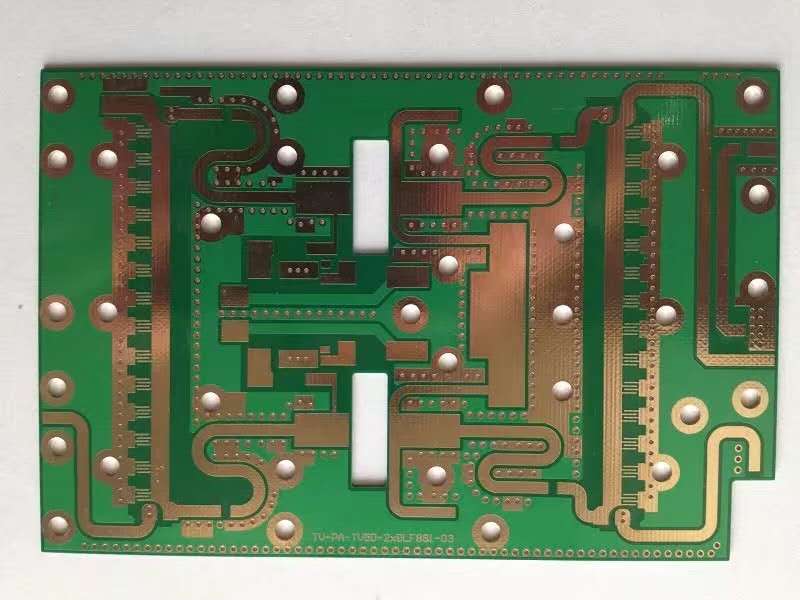

Supporting the military is something Karrtainpcb is very proud of myself, and we were contracted to assemble a PCB for use in a military communication's application. The RF PCB assembly used Rogers 4350, Rogers 4003,RT5880 material, and the board required surface mount technology for the double-sided assembly that featured 250 placements. Board specs included 3 layers, standard vias, and 1 panelization. Final measurements came to 8 × 5.75 in. We performed final testing using automated optical inspections and x-ray inspection before delivering product to the customer.

Serving industries from consumer to military, we continuously strive to build Rogers PCB products that exceed your expectations, to develop long-term customer relationships, and to become your best possible manufacturing partner.

Rogers PCB Material in Stock:

Rogers 4350B

Rogers 4003C

Rogers 3003

RT5880

RT5870

Lots of customers come to buy Rogers 4350B PCB. We keep All types Rogers 4350B material in stock, if you need any of them, welcome to contact us for the price and datasheet.

Rogers PCB Enabling step changes in high-frequency, high-speed performance for wired & wireless communications circuits worldwide with Advanced Circuit Material. Key Products/Brands include: RT/duriod® High Frequency Laminates; RO4000® High Frequency Circuit Materials; RO3000® High Frequency Laminates; and TMM® Thermoset Microwave Materials. For applications such as: Wireless Base Stations; Aerospace & Defense; Automotive; and High Speed Digital.

Rogers High Frequency Laminates

3001 Bonding Film (Thermoplastic Chloro-fluorocopolymer)

RO3000® series High Frequency Laminates (PTFE/Ceramic)

RO3035® series High Frequency Laminates (PTFE/Ceramic)

RO3200® series High Frequency Laminates (PTFE/Ceramic)

RO4000 High Frequency Laminate with TICER Foil

RO4000 laminates data sheet and fabrication guidelines: RO4003C, RO4350B

RO4400 prepreg data sheet and fabrication guidelines: RO4450B, RO4450F

RO4500 Antenna Grade Laminates for High Volume Applications

RT/duroid® 5870/5880 Glass Microfiber Reinforced PTFE Composites

RT/duroid 6002 laminate data sheet

RT/duroid 6006/6010 laminate data sheet

RT/duroid 6202 laminate data sheet

RT/duroid 6202PR laminate data sheet

TMM Thermoset laminate data sheet: TMM3, TMM4, TMM6, TMM10, TMM10i

ULTRALAM 2000 laminate data sheet

ULTRALAM 3000 LCP laminate data sheet: ULTRALAM 3850

ULTRALAM 3000 LCP Prepreg: ULTRALAM 3908

LONGLITE™ AND R/flex® Flexible Circuit Materials - Thin Dielectrics

LONGLITE™ Flex 200 Adhesiveless Materials

LONGLITE™ Flex 300 Adhesiveless Series

R/flex® 1000 Circuit Materials for Long-life Dynamic Flexing

R/flex® 1100 Circuit Materials - High Temperature Laminates

R/flex® 1500 Assembly Adhesive

R/flex® 2001 Laminates and Coverfilms

R/flex® 2005 Laminates and Coverfilms

8080 Liquid Photoimageable Covercoat data sheet

8080 Liquid Photoimageable Covercoat: LP11

8080 Liquid Photoimageable Covercoat: LP2

R/flex CRYSTAL 7500 Laminates and Coverlayers

R/flex CRYSTAL 7700 Laminates and Coverlayers

R/flex JADE A coverfilm data sheet

R/flex JADE A laminates data sheet

R/flex JADE J coverfilm data sheet

R/flex JADE J laminate data sheet

What are the Most Common Products of Rogers PCB?

The rogers PCB product range is very wide. Information about all materials can be found on the official website of the company. We will focus only on microwave materials, which have long proven themselves in our market and are actively used in various microwave applications.

RO3000 and RO3200 – PTFE and ceramic based laminates

The RO3000 and RO3200 series were the first Rogers materials developed for general use in the early 1990s. They have excellent high frequency electrical properties and high thermal stability and can be used at frequencies up to 30-40 GHz. These laminates are widely used in automotive (collision avoidance systems), satellite communication systems, GPS and wireless antennas, and cable data networks.

Low coefficient of thermal expansion (CTE) along the Z-axis provides increased reliability of plated holes. CTE along the X and Y axes are close to the same value for copper and fiberglass (FR-4), which makes it possible to use these laminates both for the production of multilayer printed circuit boards and hybrid assemblies. The glass-reinforced RO3200 series has greater mechanical strength than RO3000.

The RO3000 Series Includes:

RO3003 (Dk 3.00; Df 0.0010)

RO3035 (Dk 3.50; Df 0.0015)

RO3006 (Dk 6.15; Df 0.0020)

RO3010 (Dk 10.2; Df 0.0022)

The RO3200 series is represented by materials:

RO3203 (Dk 3.02; Df 0.0016)

RO3206 (Dk 6.6; Df 0.0027)

RO3210 (Dk 10.8; Df 0.0027)

RO4000 – Heat-Resistant Materials with Added Ceramics, Glass Fiber Reinforced

RO4000 Series Microwave roger pcb materials have been developed to, on the one hand, provide high-quality microwave characteristics similar to those of PTFE-based materials, and, on the other hand, to make it compatible with traditional processing technology of reinforced PCBs (FR-4). RO4000 materials are glass fiber reinforced with a high glass transition temperature (Tg> 280 ° C) filled with thermosetting polymer with the addition of ceramics.

What is the Grading System of Roger PCB Materials?

Unlike PTFE-based materials, RO4000 series materials do not require special chemical or plasma surface treatment in preparation for the production of plated vias. This makes the cost of manufacturing PCBs and mounting on RO4000 series microwave materials comparable to conventional epoxy laminates.

The most commonly used materials of this series: RO4003C and RO4350B – (Dk 3.38; Df 0.0027) and (Dk 3.48; Df 0.0037), respectively.

Special prepregs have been developed for these grades: RO4403C and RO4450B , which make it possible to create multilayer structures based on RO4003C and RO4350B materials, respectively. RO4403 prepreg has Dk 3.17 and Df 0.005, and refractory RO4450B prepreg has Dk 3.54 and Df 0.004. Like RO4000 materials, these prepregs are fully compatible with traditional FR4-based board technology.

What is the Function of RO4360G2 Series in Roger PCB Performance?

Another “advanced” material in this RO4360G2 series is heat-resistant, has an excellent thermal conductivity of 0.81 W / m / K, low CTE along the Z-axis, which increases the reliability of plated holes and simplifies drilling processes. It has Dk 6.15, is used in the manufacture of microwave electronics and allows operation at frequencies of 4 GHz. RO4360G2 is FR-4 compatible and offers the same reliability and consistency as RO4350B.

Laminates RO4835 (Dk 3.48, Df 0.0037@10GHf) and high frequency version RO4835T (Dk 3.33, Df 0.0030@10GHf) have been developed as an improved version of RO4350B. They have better stability at elevated temperatures and improved oxidation stability (10 times better than RO4350B).

Manufactured in the same configurations and thicknesses as the RO4350B and are IPC-4103 compliant. Applications: automotive radars and sensors, power amplifiers, phased array radars, RF components.

One of the company’s recent advances is the RO4000 LoPro laminate , which offers 10% lower insertion loss than the standard RO4000 series. Basically, these laminates are used in antenna systems, radars, digital data transmission roger pcb systems, as well as for the production of microwave components (especially power amplifiers).

RT / duroid6000 – PTFE Ceramic Laminates

There are several varieties of this type of material. Laminates RT / duroid6002 (Dk 2.94; Df 0.0012) and RT / duroid6202 (Dk 2.9; Df 0.0015) were developed in the late 1980s to address some of the shortcomings of PTFE-based materials.

The exceptional properties of these materials are the high stability of the dielectric constant in a wide temperature range and the coefficient of thermal expansion, which almost coincides with the CTE of roger pcb copper. All this makes these materials ideal for the manufacture of sandwich structures used in aerospace equipment subject to sudden changes in temperature, where there are strict requirements for the reliability of plated vias, and also requires low dielectric losses.

Ceramic Laminates for Roger PCB

This class also includes materials RT / duroid6006 and RT / duroid6010LM – ceramic PTFE laminates. The materials RT / duroid6006 (Dk 6.15; Df 0.0027) and 6010LM (Dk 10.2; Df 0.0023) were developed in the late 1970s with the aim of reducing the overall dimensions of printed circuit boards, since the high dielectric constant allows for smaller devices.

Thermal conductivity of RT / duroid 6035HTC laminate (Dk 3.5; Df 0.0013) is 2.4 times higher than that of standard RT / Duroid 6000 series models. Electrolytic foil, treated on the smooth side, which is resistant to high temperatures, allows the use of such laminate for high power amplifiers, combiners, power dividers, couplers and filters.

Thermal Testing of Microwave Boards

Results of thermal testing of a roger printed circuit board

Printed circuit board with copper base;

PCB material – Rogers;

The board is connected to the base using pressure glue;

Base thickness – 3 mm.

Test conditions and procedure:

Verification was carried out in accordance with standard tests for in-house manufactured instruments.

The thermal chamber is programmed for 3 cycles (1 cycle: -60 ° С… + 85 ° С with exposure for 30 minutes at each temperature). After 3 cycles, visual control was carried out using an MBS-10 microscope at a magnification of 16 × and 32 ×.

30 thermal cycles were carried out.

During the tests, no cracks, no delamination, no violations of the glue seam were revealed. A slight change in the color of the glue was observed (this is possible because the test sample was in a leaky volume). Conclusions based on the test results: the sample of the product corresponds to the declared properties in terms of the quality of the glue line.

Ho to Increase the Integration of Microcircuits of Roger PCB?

Multilayer roger PCB has been designed to simplify and optimize the wiring of double-sided dielectric plates. The increase in the integration of microcircuits, the provision of a significant number of interlayer connections, as well as the introduction of packages with a large number of pins – all this became the primary reason for the creation and intensive development of MPP technologies.

As the roger pcb models and technological requirements become more complex, not only the quality has increased, but also the total number of layers. As a result, sophisticated multilayer printed circuit boards can have 30-32 layers.

Features of Use

MPP are used in high-frequency devices with a regulated impedance of signal circuits and an acceptable level of electromagnetic interference.

WFP Materials

Among the main materials of multilayer rogher pcb boards are:

Rogers Ro4003 and Ro4350 series.

Glass fiber laminates FR4 K

Combination is possible among base materials. For example: use in flexible-rigid printed circuit boards polyimide (PI) with FR-4 fiberglass.

Design

The design is based on alternating thin dielectric layers combined with topology elements. When creating, the layers are connected into a single, integral multi-layer plate.

Electrical connections, depending on the pressing technique, can have both through-type vias and interlayer vias:

Outer layers to inner layers – blind vias;

Inner layers are buried vias.

Any multilayer PCB construction consists of 2 elements:

Cores– core – a dielectric layer of considerable thickness foiled on both sides.

Preprega– prepreg – dielectric foil-clad on one side or not foil-clad layer of small thickness. It acts as a connecting internuclear layer.

Layer Classification of Multilayer Roger PCB

Outlayer

Another name is editing. The essence of the layer: the installation of components and the organization of connections between located in the immediate vicinity of the board elements

Power layers

Presented in the form of solid polygons. They have minimal current resistance and low induction. Contributes to the shielding of signal layers.

Signal

You can create connections between electronic components. Feature: significant indicators of the density of communication lines

Heat-conducting

Excess heat of circuit components with increased technological values of heat release is removed and distributed

Production methods

Layer-by-layer building.

Pairwise pressing.

Combination of methods.

The main method is considered to be the method of pairwise pressing of nuclear blanks – thin double-sided boards of a certain topology. The method is implemented using cushioning glass fabric. Layer-by-layer build-up / metallization of core holes (through type) occur by a subtractive chemical method. Photoresists are used as a protective coating.

Main Equipments

CONTACT KARTAIN TECHNOLOGY

Kartain is committed to to provide you with exceptional support and satisfaction for your PCB fabrication and PCB assembly needs from QTA prototyping to High volume production.

Our experts are available to consult you for your project. So, call us anytime at 0755-23024958 or get in touch via email.

More Contact Info:

KARTAIN Factory: #3RD BUILDING HONGCHONG INDUSTRIAL DISTRICT HONGXING SONGGANG TOWN BAOAN,SHENZHEN,GUANGDONG,CHINA-518104

Office:#212 Shuiyuanju Building,Bao'an East ,Shajing Town,Bao'an District,Shenzhen,China.

Tel: +0086(755)2302 4958, 015814406156 wechat: 409387861

Fax:+0086(755)2302 4958

Email: info@kartain.com

Skype: chinacircuit

Whatsapp: +86015814406156

Website: www.kartain.com www.kartainpcb.com www.kartainfpc.com

Facebook:https://www.facebook.com/chinapcbmanufacturer/

LinkedIn: https://www.linkedin.com/in/kartainpcb/

Related Products

CopyRight 2015-2020 Kartain Technology CO.,LTD

Office Addrsss:#3RD BUILDING HONGCHONG INDUSTRIAL DISTRICT HONGXING SONGGANG TOWN BAOAN,SHENZHEN,GUANGDONG,CHINA-518104

Zip code:518104

Tel:15814406156

Website: www.kartain.com,www.kartain-tech.com

More contact infomation pls view "Contact US"

German

German Spanish

Spanish French

French Italian

Italian Portuguese

Portuguese Japanese

Japanese Korean

Korean Arabic

Arabic Russian

Russian Indonesian

Indonesian Vietnamese

Vietnamese Send Email

Send Email PCB业务

PCB业务 kartain pcb msn

kartain pcb msn kartain pcb on skype

kartain pcb on skype